Huihuang Metal: A Pioneer in Carbon Reduction for Recycled Aluminum Ingots

(A) Company Profile

Guangdong Huihuang Metal Products Co., Ltd. was established on December 15, 2009, and is located at E17, Zhaoqing Asia Metal Resources Recycling Industrial Base, Longfu Town, Sihui City, Guangdong Province. The company is a professional enterprise engaged in the production and research and development of recycled aluminum alloys. It currently has more than 260 employees, with a high-quality R&D team composed of more than 30 technical engineers led by doctors (post-doctors) and senior engineers. The company covers an area of more than 180 mu, with a factory building area of 60,000 square meters. It has an annual output of more than 100,000 tons of high-quality recycled aluminum alloys and an annual output value of over 1 billion yuan.(B) Industry Background

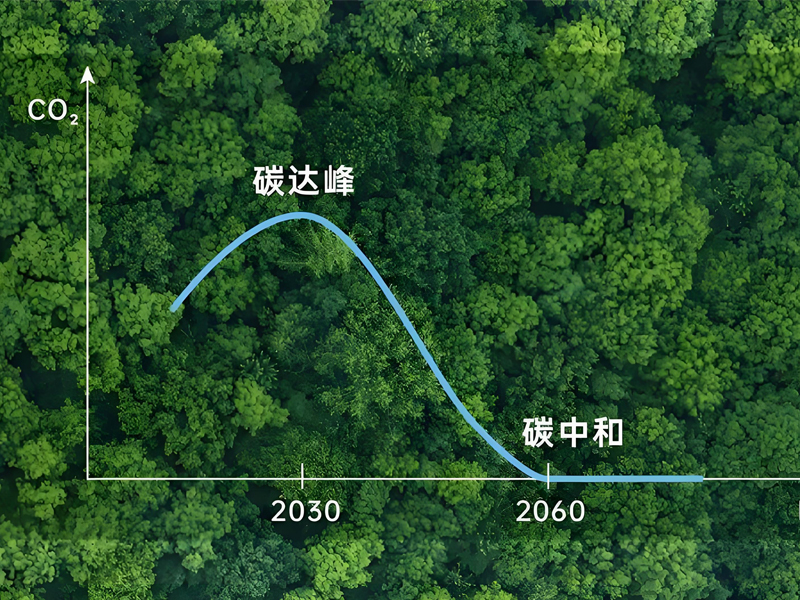

The recycled aluminum industry, as an important way for the sustainable development of the aluminum industry, has been continuously growing on a global scale. In 2021, the global production of recycled aluminum reached 35.83 million tons, accounting for about 35% of the total output of the aluminum industry. In China, the production of recycled aluminum reached 8 million tons in 2021 and 9.5 million tons in 2023, with a year-on-year growth rate of 9.8%. However, the supply of primary aluminum still dominates, and the proportion of recycled aluminum is only 17.20%. With the rapid development of energy conservation, emission reduction, and new energy vehicles, the aluminum industry is accelerating its shift towards green, low-carbon, and high-quality development. The recycled aluminum industry has significant social benefits in terms of resource conservation, energy conservation, emission reduction, and environmental protection, and has become an important part of the global aluminum industry. In the future, the trends of capacity expansion, technological innovation, green development, and international development in the recycled aluminum industry will become more prominent.II. Carbon Reduction Measures and Achievements

(A) Technological Innovation Promotes Carbon Reduction

Guangdong Huihuang Metal Products Co., Ltd. has been constantly carrying out technological innovation in the production process of recycled aluminum ingots. In terms of material research and development, according to customer needs, the company provides research services for improving the performance of aluminum alloy materials and has developed a variety of new aluminum alloy materials, such as high thermal conductivity casting aluminum alloys, high-temperature-resistant aluminum alloys, corrosion-resistant aluminum alloys, and high-strength aluminum alloys. These materials reduce energy consumption in the production process while ensuring performance, thereby reducing carbon emissions.

In terms of process research, the company has conducted in-depth studies on the castability, fluidity, and mold erosion of materials. By optimizing process parameters, production efficiency has been improved, and energy waste has been reduced. For example, the optimized casting process makes the fluidity of molten aluminum better, reduces the scrap rate in the casting process, and lowers energy consumption and carbon emissions.(B) Standard Certification Shows Results

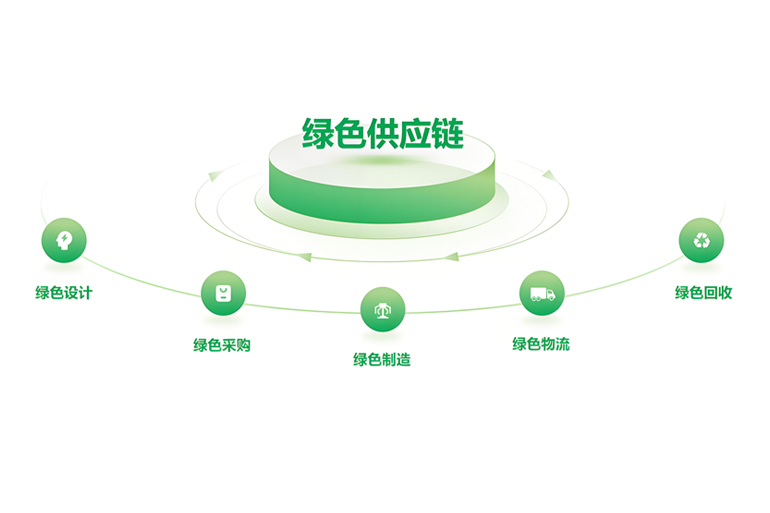

The company has successively passed certifications for quality, environment, product carbon footprint, and recycling standard systems. These certifications not only reflect the company's excellent performance in product quality and environmental protection but also provide strong support for the company's carbon reduction work.Through product carbon footprint certification, the company can accurately measure and evaluate the carbon emissions of products throughout their life cycle and then take targeted measures to reduce carbon emissions. Meanwhile, the recycling standard system certification ensures that the company can effectively recycle and utilize waste aluminum materials in the production process of recycled aluminum ingots, reducing the demand for primary aluminum and lowering carbon emissions in the aluminum production process.

(C) Capacity Utilization Helps Environmental Protection

The company has strong production capacities, with an extrusion aluminum production capacity of 6,000 tons per year and an aluminum ash resource utilization and treatment capacity of 60,000 tons per year. The company makes full use of these capacities to achieve the goals of carbon reduction and environmental protection.

In the extrusion aluminum production process, the company adopts advanced production processes and equipment to improve energy utilization efficiency and reduce carbon emissions. Meanwhile, the company conducts resource utilization of aluminum ash generated in the production process and processes it into a series of environmental protection products. In this way, the company not only reduces the environmental pollution caused by aluminum ash but also realizes the recycling of resources and reduces carbon emissions.

For example, the company processes aluminum ash into water purification agent products such as polyaluminum chloride, sodium tetrahydroxyaluminate, decolorizing agents, and aluminum sulfate, which play an important role in fields such as sewage treatment. Meanwhile, the company has obtained exemptions for the utilization of hazardous wastes and provides customers with compliant disposal services, further promoting the recycling of resources and environmental protection.

(A) Great Significance of Carbon Reduction

Significance for the Environment: The carbon-reducing production of recycled aluminum ingots is of crucial significance for the environment. In the production process of aluminum, the traditional electrolytic aluminum production method has high energy consumption and large carbon emissions. Taking the production of one ton of electrolytic aluminum as an example, it requires 13,500 kWh of electricity, and the carbon dioxide emission is about 12 tons. However, the production of one ton of recycled aluminum only consumes 400 - 700 kWh of electricity, and the carbon dioxide emission is only 0.23 tons. Guangdong Huihuang Metal Products Co., Ltd. has greatly reduced carbon emissions by vigorously developing the production of recycled aluminum ingots, which helps alleviate global climate change and reduce the adverse impact of greenhouse gases on the atmospheric environment. Meanwhile, it reduces the demand for the exploitation of natural resources and decreases the damage to the ecological environment caused by bauxite mining and other activities, thus protecting the ecological balance.(B) Promising Future Development